Indonesia is a high-potential market—but only if you meet SNI requirements. For faucet» and plumbing wholesalers, SNI 122:2022 is now the key standard that determines whether your products can legally enter and stay in the market.

Enforcement is tightening. Without proper SNI certification, shipments risk delays, rejection, or loss at customs. With it, you gain smoother clearance, buyer confidence, and long-term market access.

This guide explains what wholesalers need to know—and how to avoid costly compliance mistakes when entering Indonesia.

The Legal and Regulatory Framework

Faucet compliance in Indonesia is governed by a clear legal hierarchy that determines when SNI standards are voluntary and when they become mandatory.

At the core is Law No. 20 of 2014, which authorizes BSN to issue standards and KAN to accredit certification bodies. Enforcement is supported by Consumer Protection Law No. 8 of 1999, making the sale of non-compliant products a legal violation where SNI is mandatory. Government Regulation No. 34 of 2018 further clarifies that SNI becomes compulsory once enforced by a technical ministry, such as the Ministry of Industry.

SNI 122:2022 (Faucets) is currently in a transition stage. While not yet formally mandatory, recent enforcement trends in related water and sanitation sectors strongly indicate that mandatory adoption is approaching. As a result, many manufacturers already treat compliance as essential for future market access.

Comprehensive Analysis of SNI 122:2022

SNI 122:2022 aligns Indonesian faucet requirements with international standards. Adopted on July 18, 2022, it replaces the outdated SNI 03-0122-1998 and reflects a modernized technical framework.

Scope and Product Categorization

SNI 122:2022 covers most supply fittings used in residential and commercial applications. It defines 15 product categories, and correct classification is essential, as endurance and flow-rate tests vary by product type.

| Category No. | Product Designation | Description and Application |

|---|---|---|

| 1 | Bath supply fitting | Faucets designed for filling bathtubs; often high-flow requirements. |

| 2 | Bidet supply fitting | Fixtures for personal hygiene (bidet). |

| 3 | Clothes washer supply fitting | Valves connecting to washing machines; high pressure resilience required. |

| 4 | Drinking fountain supply fitting | Public or private drinking water dispensers. |

| 5 | Kitchen supply fitting | Kitchen sink faucets (mixing or single). |

| 6 | Lavatory supply fitting | Faucets for bathroom sinks (washbasins). |

| 7 | Lawn faucet | Outdoor taps/hose bibs; requiring weather resistance. |

| 8 | Automatic faucet | Sensor-operated or metering faucets; electronic component testing applies. |

| 9 | Shower head faucet | Standard showerheads. |

| 10 | High-efficiency shower head | Showerheads meeting specific water-saving flow rates. |

| 11 | Hand shower faucet | Hand-held shower units. |

| 12 | High-efficiency hand shower | Water-saving hand shower units. |

| 13 | Body spray faucet | Side jets or body sprayers in shower systems. |

| 14 | High-efficiency body spray | Water-saving body sprays. |

| 15 | Supply stop | Stop valves/angle valves used for isolation. |

Harmonization with International Standards (ASME/CSA)

SNI 122:2022 is based on the UPC and aligned with ASME A112.18.1 / CSA B125.1, a harmonization supported by the USAID/ANSI Standards Alliance to reduce trade barriers.

For global manufacturers, this means faucets designed to meet ASME standards generally meet SNI technical requirements. However, local testing or verification by an Indonesian accredited lab is still required—foreign certificates alone are not sufficient.

Technical Requirements and Testing Protocols

SNI 122:2022 certification requires thorough lab testing to verify safety, durability, and hygiene, including hydraulic performance, material quality, and surface finish.

Pressure and Hydrostatic Integrity

Pressure resistance is the most critical safety parameter. Faucets must withstand high internal water pressures without leaking, bursting, or deforming.

- Working Pressure vs. Test Pressure:

-

- Working Pressure: Faucets typically operate between 20–125 psi (140–860 kPa).

- Hydrostatic Test: Tested well above maximum pressure (e.g., 500 psi / 3,450 kPa) to ensure durability and resistance to water hammer.

- Low-Pressure Performance: Verified to maintain minimum flow (≈0.8 gpm) even at 20 psi, accommodating low-pressure areas.

- Test Methodology:

Certification uses hydraulic (water) testing, not pneumatic, for safety and accuracy. Faucets are pressurized on a test rig, and any leaks or structural failures result in a fail.

Material Composition and Health Safety

The material of the faucet body is scrutinized to prevent heavy metal contamination of drinking water.

- Brass & Lead: Modern faucets must be lead-free; brass (copper-zinc) is standard with strictly regulated Pb content.

- Extraction Testing: Faucets undergo leaching tests (up to 19 days) for lead, cadmium, and other toxins; limits align with SNI/NSF standards (e.g., Q ≤ 5 µg).

- Alternative Materials:

- Stainless Steel (304/316): Corrosion-resistant, lead-free, popular in premium segments.

- Zinc Die-Cast (Zamak): Common for handles/lower-cost bodies; requires rigorous corrosion testing.

Coating and Finish Durability

- Corrosion Resistance (Salt Spray):

- Standard: ASTM B117

- Procedure: Faucets exposed to 5% NaCl fog at 35°C

- Duration: High-quality chrome typically 96–200+ hours without blistering/corrosion

- Implication: Failures indicate poor plating control (e.g., thin nickel underlayer)

- Coating Thickness & Adhesion:

- Thickness: Chrome plating usually 10–15 µm Ni + 0.2–0.5 µm Cr; industrial ranges up to 50 µm

- Adhesion: Tested via ASTM B571 / D3359 (Tape Test); peeling = fail

Mechanical Endurance (Life Cycle)

- Cycle Count: Handle is operated 250,000–500,000 times for domestic faucets.

- Conditions: Tested under water pressure; must show no leaks or functional wear.

- Purpose: Verifies durability of internal cartridge and O-ring seals.

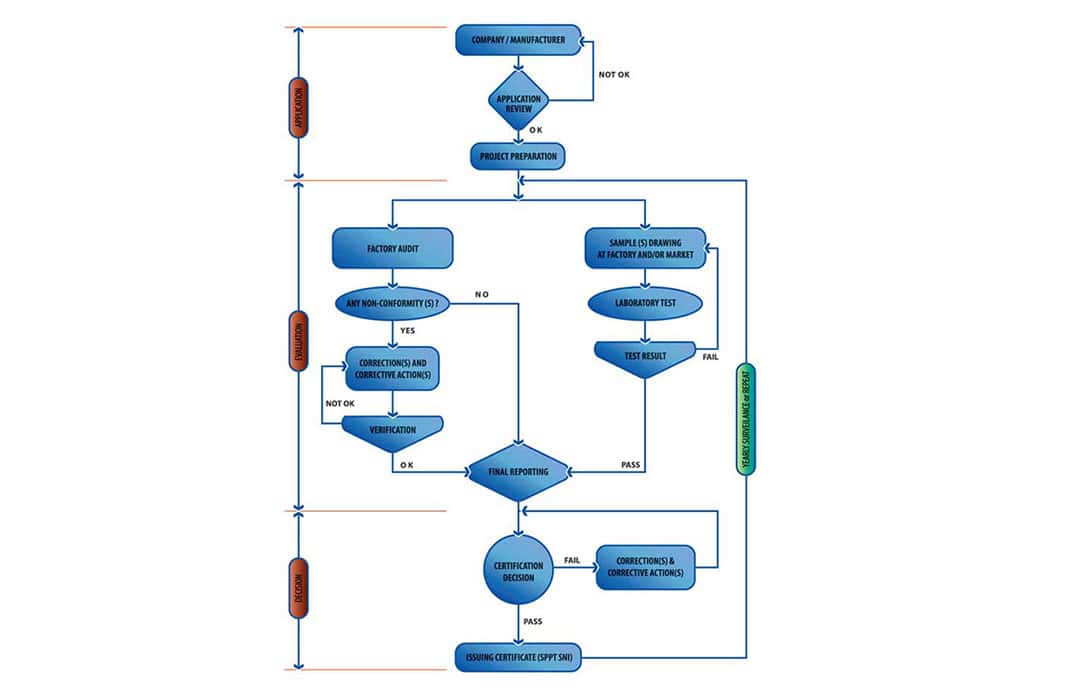

Conformity Assessment Procedures: The “Type 5” Scheme

SNI certification goes beyond lab tests. Scheme Type 5» assesses both product quality and manufacturing consistency, making it more rigorous than basic batch inspection.

Stage 1: Application and Administrative Review

The process begins with the manufacturer (or their authorized representative) submitting a formal application to an accredited LSPro (e.g., IAPMO, TÜV Rheinland).

- Documentation: Essential documents include the Industrial Business License (IUI), Company Registration (NIB), Trademark Certificate (HAKI), and ISO 9001 Quality Manual.

- Local Representative: For foreign manufacturers, a Local Representative (importer/distributor) must be appointed. This entity acts as the legal holder of the certificate and bears liability for the product in the Indonesian market.

Stage 2: Quality Management System (QMS) Audit

An audit team from the LSPro travels to the manufacturing facility (whether in Indonesia or abroad).

- Objective: To verify that the factory’s Quality Management System (typically ISO 9001:2015) is implemented effectively and ensures consistent production compliance with SNI 122:2022.

- Focus Areas: The auditors scrutinize incoming material quality control (e.g., brass composition checks), in-process inspections (leak testing on the line), calibration of test equipment, and complaint handling procedures.

- Non-Conformity: If major non-conformities are found, the process halts until corrective actions are verified.

Stage 3: Sampling and Testing

During the factory audit, the auditors perform random sampling of the products to be certified.

- Selection: Samples are pulled directly from the production line or the warehouse.

- Quantity: Typically, 3 units per model/family are required for testing.

- Chain of Custody: The samples are sealed by the auditor and shipped to an accredited laboratory in Indonesia. The manufacturer cannot send their own pre-selected samples; the auditor must witness the selection to prevent “Golden Sample” fraud.

Stage 4: Evaluation and Issuance

The LSPro reviews two key documents: the Factory Audit Report and the Laboratory Test Report.

- Decision: If both reports show full compliance, the LSPro issues the SPPT SNI (Product Certificate for the Use of the SNI Mark).

- Validity: The certificate is valid for 4 years.

Stage 5: Surveillance and Maintenance

Certification requires ongoing maintenance. The LSPro conducts Surveillance Audits annually (or at set intervals, e.g., Month 12, Month 24, Month 36) to ensure continued compliance.

- Scope: Surveillance involves a repeat of the factory audit and often includes re-testing of samples.

- Market Surveillance: Regulators may also purchase products from retail shelves to test them. If a product fails market surveillance, the SPPT SNI can be suspended or revoked.

Costs and Logistics

The Type 5 scheme represents a significant investment.

- Audit Costs: Manufacturers must cover the travel, accommodation, and man-day fees for the auditors. For overseas factories (e.g., in China or Europe), this can cost thousands of dollars per visit.

- Testing Fees: Laboratory fees for full SNI 122:2022 testing (including chemical extraction and 500k cycle testing) are substantial.

- Timeframe: The entire process, from application to issuance, typically takes 3 to 6 months, depending on lab capacity and audit scheduling.

Accredited Certification Bodies (LSPro)

SNI certificates are valid only if issued by LSPro accredited by KAN for SNI 122:2022. Manufacturers must check that their partners hold the appropriate accreditation.

PT IAPMO Group Indonesia

- Profile: A subsidiary of the IAPMO Group (USA), they are a dominant player in the plumbing sector.

- Capabilities: IAPMO was directly involved in drafting SNI 122:2022 and possesses a dedicated plumbing testing laboratory in Cikarang, West Java.

- Strategic Fit: They are the “specialist” choice for plumbing. Their lab is specifically equipped for the complex endurance and hydraulic tests required by SNI 122:2022.

- Services: They offer a “one-stop” service including testing and certification, and can often bundle SNI certification with UPC certification for the US market.

TÜV Rheinland Indonesia

- Profile: A global testing giant with a strong presence in Indonesia (LSPr-026-IDN).

- Capabilities: Their scope is massive, covering automotive, electrical, and mechanical products. They support both voluntary and mandatory SNI schemes.

- Strategic Fit: Ideal for large conglomerates that manufacture a wide range of products (e.g., a company making both faucets and electronic appliances) and want to consolidate certification providers.

SGS Indonesia

- Profile: Another global leader in inspection and certification.

- Capabilities: Accredited by KAN and registered with the Ministry of Industry. They focus heavily on trade facilitation and market access.

- Strategic Fit: Strong in logistics and supply chain verification, making them a good partner for importers who need assistance with the complex documentation required for Indonesian customs.

Other Bodies (Sucofindo, BKI)

- Sucofindo: A state-owned enterprise often favored for government-linked projects and mandatory verification.

- Biro Klasifikasi Indonesia (BKI): While primarily marine-focused, they have expanded into industrial certification.

| LSPro | Specialization | Key Advantage | Location of Lab |

|---|---|---|---|

| IAPMO | Plumbing & Mechanical | Deep technical expertise; drafted the standard. | Cikarang, Indonesia |

| TÜV Rheinland | General Industrial/Electrical | Global network; German engineering reputation. | Jakarta/Various |

| SGS | Trade & Inspection | Strong customs/import support. | Jakarta/Various |

Strategic Market Implications

The implementation of SNI 122:2022 creates both barriers and opportunities in the Indonesian market.

Barriers to Entry and “Dumping” Prevention

Type 5 certification is a strong non-tariff barrier—low-cost manufacturers using poor materials or lacking quality control cannot pass tests or audits.

- Impact: This is expected to clean up the market, reducing the prevalence of cheap, unbranded faucets that fail prematurely.

- Dumping Ground Defense: As noted in industry reports, Indonesia has historically been a destination for substandard goods. Mandatory SNI effectively closes the border to these products, as Customs (Bea Cukai) will require the SPPT SNI document for clearance.

The Role of the Local Representative

For international brands (e.g., Kohler, Toto, Grohe), the requirement to appoint a local representative is strategic.

- Liability: The local entity holds the certificate. If the product fails market surveillance, the local entity faces the legal consequences.

- Control: Brands should choose local partners carefully. Holding the SNI license gives distributors leverage, so many multinationals set up a local subsidiary (PT PMA) to retain control of IP and market access.

Economic and Health Outcomes

The standardization of faucets is directly linked to broader economic goals.

- Public Health: By limiting lead leaching and ensuring hydraulic integrity, SNI 122:2022 reduces waterborne health risks.

- Tourism & Investment: Improved sanitation infrastructure is cited as a key factor in boosting tourism and foreign investment. Reliable plumbing is invisible when it works, but economically damaging when it fails.

Conclusion and Recommendations

The shift toward SNI 122:2022 compliance is inevitable. Even before the mandatory decree, the market is already moving in this direction.

- For Manufacturers:

- Act Now: Start certification to avoid future bottlenecks.

- Gap Analysis: Check Lead content, coating thickness (>10 µm Ni + Cr), and pressure resistance (500 psi).

- Budget: Plan for Type 5 audits and testing.

- For Importers:

- Vendor Verification: Confirm ISO 9001 and internal testing.

- Legal Structure: Secure appointment letters and ensure warehouse compliance for LSPro sampling.

Complying with SNI 122:2022 positions your brand as premium, trusted, and sustainable—a key differentiator in Indonesia’s competitive plumbing market.

FAQs

About Luxuryhome

Luxuryhome is not just a faucet manufacturer or wholesaler, but more like a partner who can provide you with more added value.

We are united in our determination to produce China-made bath and kitchen fixtures adhering to the highest ethical principles. You have our promise!

More post you may interested in