Hey there! If you’re a wholesaler or sourcing professional, you know balancing cost and quality is tough. With faucets, chasing the lowest price creates “predictable liability”—profit turns into failures and warranty claims. Our goal is to help you shift your strategy: become an Active Quality Gatekeeper. By setting Checkpoints for Wholesale Faucets, you build trust and reliability—a lasting edge price-only competitors can’t match.

Foundational Integrity—Material Science and the Lead-Free Imperative

The first, and arguably most important, checkpoint is the material itself. This foundational choice dictates the faucet’s resistance to corrosion, its lifespan, and your associated risk.

Deconstructing the Faucet Body: Durability Benchmarks

You can often tell a lot about a faucet just by picking it up. Heavier faucets typically signal superior, solid metal construction.

- Solid Brass: The industry benchmark, brass is durable and corrosion-resistant, lasting 15–20 years. Its copper content also provides natural antimicrobial benefits.

- Stainless Steel (304/316): A premium, 100% lead-free choice», safe for drinking water. It resists wear, scratches, and rust, with a lifespan of 15–20 years. Grade 316 is best for coastal markets.

- Zinc Alloy: A budget option with a short 3–5 year lifespan. It corrodes easily and often fails, creating high risks for warranties and contractor trust.

| Material | Average Lifespan (Years) | Corrosion Resistance (1-5) | Lead Content | Ideal Application | Relative Cost Index (1-5) | Key Physical Identifier |

|---|---|---|---|---|---|---|

| Solid Brass | 15-20 | 4 | Low (≤0.25%) | All-purpose, especially hard water areas | 4 | Heavier weight, solid feel |

| Stainless Steel | 15-20 | 4 | 100% Lead-Free | High-use kitchens, health-conscious settings | 4 | Sleek, non-porous surface |

| Zinc Alloy | 3-5 | 1 | Can be high | Temporary or low-use applications | 2 | Lighter weight than brass |

The Regulatory Mandate: Navigating the Lead-Free Definition

This is a legal and ethical checkpoint you cannot skip.

- The Law: Since the 2014 regulatory update, all faucets sold for potable water use in the U.S. must contain no more than a weighted average of 0.25% lead across their wetted surfaces.

- Modern Brass Chemistry: High-quality manufacturers have replaced lead (which helped with casting) with safer elements like bismuth, silicon, or phosphorus. Understanding the specific alloy used shows a manufacturer’s commitment to quality beyond basic compliance.

- Your Due Diligence: A manufacturer’s verbal claim of “lead-free” is insufficient. You must demand and verify third-party certification as the only acceptable checkpoint.

The Heart of the Matter: Checking a Faucet’s Insides for Long-Term Performance

While the faucet body provides strength, the valve controls performance, reliability, and feel. As the most stressed part, it’s also most prone to wear. A manufacturer’s valve choice reveals whether they prioritize long-term quality or short-term savings.

Valve Cartridge Technology: Where Reliability Begins

The valve cartridge controls water flow and temperature, and its technology determines whether a faucet stays drip-free for years or needs constant repairs.

- Ceramic disc cartridges use two polished discs to form a watertight seal, resisting wear and buildup for smooth, leak-free performance that lasts a faucet’s lifetime.

- A Quick Comparison: Ball, Compression, and Cartridge Valves:

- Compression Valves: Oldest and leak-prone; rubber washer wears quickly, causing drips and frequent replacements—poor for quality stock.

- Ball Valves: Found in older single-handle faucets; rotating ball with many parts like O-rings and seals can wear and leak over time.

- Cartridge Valves (Non-Ceramic): Self-contained and replaceable; better than compression and ball valves but rubber and plastic parts still wear eventually.

Not all ceramic discs are equal. Premium brands use innovations like diamond-embedded discs to prevent buildup and last ten times longer. Commercial cartridges may use solid brass with self-lubricating O-rings. Sourcing from specialists like Kerox or Citec shows a manufacturer prioritizes quality.

Beyond the Cartridge: Checking the Other Parts

The cartridge is key, but a faucet’s other parts also affect performance and lifespan, often failing first in lower-quality products.

- Hoses and Supply Lines: Leaks often come from flexible hoses. Quality faucets use braided stainless steel (Grade 301/304) and brass or steel nuts. Check the inner tube—strong chemical smells indicate cheap materials.

- Aerators: Shape the water stream and improve efficiency. Premium faucets use pressure-compensating aerators from makers like Neoperl for consistent, splash-free flow.

- O-Rings and Seals: Rubber or silicone parts create watertight seals. High-grade, self-lubricating O-rings ensure long, leak-free life and smooth movement.

Looks That Last: A Guide to Faucet Finishes

A faucet’s finish protects the metal from rust, scratches, and harsh cleaners. The application method affects durability and appearance over time. For wholesalers, a failing finish often causes complaints and warranty claims.

Finishing Technologies and How They Affect Lifespan

Different finishing processes give you very different levels of durability. Understanding these technologies will help you judge the long-term value and toughness of a product.

- Physical Vapor Deposition (PVD): The top-tier finishing method. Vaporized metals like titanium bond to the faucet surface, creating a hard, dense layer resistant to scratches, tarnish, corrosion, and fading—often four times harder than chrome.

- Electroplating: Traditional chrome finish applied via chemical baths and electric current. Quality plating has ≥8 μm nickel layer and passes 24-hour salt spray tests. Thin plating (3–4 μm) oxidizes, blisters, and peels quickly.

- Powder Coating: Dry colored powder baked onto the faucet for matte finishes. Trendy but less durable than PVD or high-quality electroplating; prone to chipping and scratches.

The Non-Negotiable Gates—Mandatory Certifications

Let’s be clear: certifications are not marketing features; they are the absolute, non-negotiable foundation of a product’s legality and safety. This “trifecta” provides objective, third-party proof of quality.

Health, Safety, and the New Standard (NSF)

- Cornerstone Standard: NSF/ANSI/CAN 61 is mandatory for all potable water use and limits the leaching of lead and contaminants.

- Critical Update: Confirm compliance with NSF/ANSI/CAN 61: Q ≤ 1. Since Jan 1, 2024, the lead limit was cut five-fold. Using products meeting only the old standard risks non-compliance for new installations.

Code Compliance and Market Access

- Market Access Requirement: The cUPC® mark, along with other recognized international certifications, signifies compliance with plumbing codes and standards used in various countries. These marks are often required for legal installation and market access worldwide. Layer of

- Assurance: The cUPC and other certification processes include unannounced factory audits, ensuring the manufacturer is continuously monitored—providing an added layer of quality assurance for global buyers.

Water Efficiency and Performance (WaterSense)

- Dual Purpose: The WaterSense» label (max 1.5 GPM for bath faucets) is a powerful marketing tool that appeals to efficiency-conscious consumers.

- De Facto Requirement: Even though it’s voluntary federally, WaterSense compliance is mandatory code in key markets like California and New York City.

Vetting the Process—Manufacturer and Supply Chain Integrity

A quality product is the result of a quality process. Your QC framework must extend beyond the physical faucet to audit your partner’s operations.

The QC Audit Framework

- Raw Material Verification: Demand transparency! A premier manufacturer should employ an in-house spectrometer to analyze the chemical composition of brass ingots before they even start production . Ask for spectroscopy reports .

- In-Process Checks: Make sure every single faucet body undergoes a pressure test after casting to catch microscopic porosities or cracks early .

- Endurance Testing: Verify that the manufacturer subjects their products to rigorous tests: Lifecycle Endurance Testing (simulating years of use on cartridges) and Corrosion Resistance Testing (using neutral salt spray chambers).

The Pre-Shipment Inspection Protocol: Your Final Check

Before shipment or upon arrival, perform a random-sample inspection to ensure products match your order. This should be standard in any supply agreement.

- Visual & Tactile Check: Inspect faucets for scratches, blemishes, uneven plating, and color consistency. Test handles and swivel spouts for smooth, solid operation.

- Dimension & Weight Check: Use calipers and scales to confirm dimensions and weight match specs. Large differences may indicate material changes or thinner walls.

- Component & Accessory Check: Verify all parts—hoses, mounting hardware, gaskets, drain assembly, and cartridge type—are included and correct.

- Packaging & Labeling Check: Ensure boxes are strong, labels and logos match the order, and required certifications (cUPC, NSF, etc.) are displayed correctly.

The Bigger Picture: Warranty, Spare Parts, and After-Sales Support

Wholesale success depends on reliability. Faucet quality includes materials, certifications, and the manufacturer’s support, warranties, and spare parts—vital for contractors.

Understanding Warranties: Finding True Long-Term Value

- Coverage: Good warranties separate mechanical and finish coverage. Long mechanical warranties indicate quality cartridges; finish coverage reflects durable PVD or plating. Watch for exclusions like improper installation, harsh cleaners, or hard water damage.

- Finishes & Usage: “Living finishes” like Oil Rubbed Bronze change over time; warranties usually cover function, not appearance. Commercial installations may have shorter warranty periods.

- Claims Process: Check the manufacturer’s claim procedure—requirements to return parts and labor coverage are key, as most do not cover labor costs.

Why a Spare Parts Program is a Game-Changer

For plumbers and contractors, time is money. Quick faucet repairs and an accessible spare parts program are key for professional-grade products.

- Spare Parts Matter: For plumbers and contractors, quick repairs save time and money. A strong spare parts program prevents unnecessary faucet replacements, reduces downtime, and builds customer loyalty.

- Evaluating Suppliers: Check a manufacturer’s commitment to parts—deep inventory, easy ordering, and guaranteed availability after models are discontinued. Lack of a parts program shows focus only on initial sales.

Finding a Reliable Supplier: An Example

Once you understand the quality checkpoints, the next step is finding a reliable supplier. In China, a major faucet producer, suppliers like Luxuryhome» stand out by controlling every step from design to packaging to meet international standards. A trustworthy supplier should provide test reports and complete certification documentation.

Here are some key advantages to look for in a supplier, using Luxuryhome as a model:

- Strict Quality Control: They manage the entire production process, from raw material inspection to final assembly, to ensure consistency and durability.

- High-Quality Materials: They use premium materials like high-quality brass and durable 304 stainless steel for their faucets.

- Advanced Finishing: They utilize modern surface treatment methods like PVD and high-quality electroplating for durable and stylish finishes.

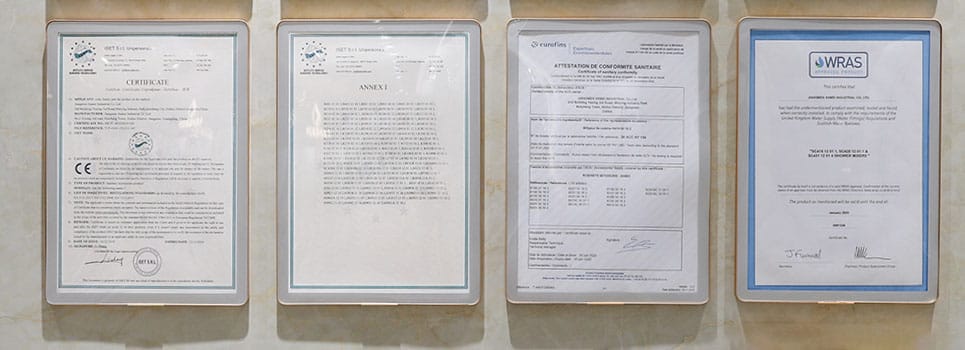

- Comprehensive Certifications: Their products meet various international standards, with certifications like cUPC, NSF, CE, and WRAS, which is crucial for market access.

- Verified Performance: They can provide test reports for their products, covering various quality and durability assessments.

- Warranty Support: They offer a limited warranty on their products, signaling confidence in their manufacturing.

Conclusion: Becoming the Trusted Quality Partner

Effective wholesale faucet sourcing requires a Lifecycle Value Sourcing Model—building a sustainable business that minimizes risk and maximizes long-term trust.

Final Actionable Checkpoints for Wholesale Faucets to Become the Active Quality Gatekeeper:

- Certification Trifecta: Ensure all potable water products have NSF/ANSI/CAN 61: Q ≤ 1 and cUPC certifications.

- Prioritize Materials: Choose Solid Brass or Stainless Steel over short-lifespan Zinc Alloy.

- Supplier Audits: Require QC documentation, material reports, and in-house endurance testing.

- Spare Parts Program: Stock high-turnover wear parts to become an indispensable service provider.

Implementing these quality checkpoints protects your bottom line and strengthens your reputation as a trusted source of reliable, compliant, professional-grade products—a competitive edge that pays off for years.

FAQs

About Luxuryhome

Luxuryhome is not just a faucet manufacturer or wholesaler, but more like a partner who can provide you with more added value.

We are united in our determination to produce China-made bath and kitchen fixtures adhering to the highest ethical principles. You have our promise!

More post you may interested in