Welcome to the vibrant (and sometimes complex) world of the Brazilian sanitary metals market! If you are looking to manufacture or import faucets, mixers, or water purifiers for Brazil, you’ve probably heard the name “INMETRO” thrown around a lot. It can be a bit intimidating, but don’t worry—we’re going to break it down simply.

Think of this guide as a conversation with a local expert. We’ll skip the heavy academic jargon and get straight to what you actually need to know to get your products on the shelves without any legal headaches.

The Big Picture: How It Works

In Brazil, product compliance is governed by INMETRO», which sets the regulations, ABNT, which issues the technical standards, and OCPs—the accredited third-party bodies that test your products and issue the certificates.

Here is the most important thing you need to know right now: Not all faucets are treated equally.

Brazil splits these products into two distinct “buckets” based on risk:

- Just a Faucet (Mechanical): If it just opens and closes water, it’s usually Voluntary.

- Improving Water (Health): If it filters or purifies water, it is Mandatory.

Let’s dive into each one.

The Voluntary Path: Standard Faucets & Mixers

Even after Portaria 406/2014 was revoked, voluntary certification remains key in Brazil, driven by the PSQ under the PBQP-H program.

Market Drivers for Voluntary Compliance

Why would a manufacturer voluntarily subject themselves to the costs and scrutiny of certification?

- Big Retailers: Stores like Leroy Merlin won’t stock uncertified products to avoid liability.

- Government Contracts: Compliance with PBQP-H (mirroring INMETRO tests) is required for public projects.

- Consumer Trust: The INMETRO “N” mark reassures buyers your faucet won’t fail quickly.

Scope of the Voluntary Regime

The voluntary regime (and the corresponding NBR standards) covers a specific range of products:

- Torneiras (Faucets): Devices for regulating water flow, including pillar taps, bib taps, and single-hole mixers.

- Misturadores (Mixers): Devices that mix hot and cold water, either via dual handles or single-lever (monocomando) cartridges.

- Registros (Stopcocks/Valves): Specifically Registros de Pressão (Globe valves for flow control, e.g., in showers) and Registros de Gaveta (Gate valves for maintenance isolation).

- Sifões (Siphons): Waste traps for sinks and basins.

The faucet’s mechanism (compression washer or ceramic cartridge) determines the applicable standard subsection, but all are classified as sanitary metals.

Technical Compliance Overview: ABNT NBR 10281

ABNT NBR 10281 is the foundation of faucet quality in Brazil, defining the engineering, safety, and durability requirements for all sanitary metals. Compliance serves as the legal benchmark for defects, even if certification is voluntary.

Material Composition and Safety

- Heavy Metal Control: Limits on lead, cadmium, and arsenic align with Ministry of Health Ordinance GM/MS nº 888/2021.

- Corrosion Resistance: Dezincification Resistant (DZR) brass is required in areas with aggressive water to prevent structural failure.

- Surface Treatment: Salt spray testing ensures plating durability; high-quality faucets achieve 144h+ exposure through multi-layer processes (Cu strike → Acid Cu → Semi-bright Ni → Bright Ni → Chrome).

Dimensional Standards

- Thread Compatibility: Inlet connections follow NBR 8133 to ensure proper sealing and avoid cross-threading.

- Aerator Threads: Standardized for easy replacement of flow restrictors.

Hydrostatic & Pneumatic Integrity

- Tightness Tests: Faucets are tested at 1.5–2x nominal pressure (up to ~4 bar/58 psi) to detect leaks or porosity.

- Envelope Sealing: Ensures no water escapes from the body or stem during operation.

Lifecycle and Wear Resistance

- Cycle Testing: Simulates long-term use:

- Compression washers: 50,000 cycles

- Ceramic 1/4-turn mechanisms: 200,000 cycles

- Post-Test Verification: Faucets must remain leak-free, confirming material and mechanism durability.

Hygienic Safety & Acoustic Considerations

- Acoustic Behavior: Though not strictly enforced in Brazil, NBR 10281 notes noise generation due to cavitation or turbulence. High-end faucets may target quieter acoustic classes.

- Functional Integrity: Ensures the faucet operates reliably without compromising water quality.

The Mandatory Regime: Equipment for Water Improvement

Faucets with filters are treated as “Health Products,” regulated by Portaria 344/2014 and ABNT NBR 16098.

Defining the Scope

The mandatory scope covers all Equipment for Improving Drinking Water Quality (Apparelhos para Melhoria da Qualidade da Água para Consumo Humano), including:

- Torneiras com Filtro: A single unit combining a faucet and a filtration canister.

- Purifiers (Purificadores): Wall-mounted or counter-top units connected to the mains.

- Gravity Filters: Clay filters (Filtros de Barro) or plastic pitchers.

Exclusions: Devices that only transport water (e.g., bottles) or treat non-potable water are excluded. The focus is on Point-of-Use (POU) systems that improve already potable water.

Technical Requirements: ABNT NBR 16098

Certification under ABNT NBR 16098 is rigorous, reflecting the biological and chemical risks of water treatment. Key requirements include:

- Particle Retention

- Tests mechanical filtration with standardized dust.

- Classes:

- A (0.5–1 µm) – fine cysts/sediment, advanced membranes

- C (5–15 µm) – typical carbon block

- F (50–80 µm) – basic sediment

- Class must appear on packaging.

- Free Chlorine Reduction

- Removes taste/odor via activated carbon.

- Must reduce ≥75% throughout filter life.

- Bacteriological Efficiency (Optional)

- Reduces E. coli by ≥99% (2-log).

- Requires silver, UV, ozonation, or <0.2 µm membranes.

Administrative Requirements: Registro de Objeto

Unlike voluntary products, mandatory products require a formal registration with INMETRO.

- Orquestra System: The manufacturer creates an account in INMETRO’s Orquestra system.

- Upload: They upload the Certificate of Conformity issued by the OCP.

- Registration Number: INMETRO issues a unique registration number (e.g., 001234/2025). This number must be printed on the product packaging under the INMETRO seal.

- Enforcement: Market surveillance officers scan this number to verify validity. If the certificate expires or is suspended, the registration is cancelled, and sales must stop immediately.

Certification Procedures and Conformity Assessment Models

The path to certification, whether mandatory or voluntary, follows structured models defined in the General Requirements for Product Certification (RGCP).

The Certification Process (Step-by-Step)

- Application: Manufacturer submits technical drawings, memorials, and component lists to an accredited OCP.

- Certification Plan & Family Concept: OCP defines product families; testing the most complex model validates simpler variants.

- Initial Audit: Auditor inspects the factory to verify the Quality Management System (FPC), traceability, and routine production tests (e.g., 100% pressure testing).

- Sample Collection & Testing: Random samples are taken from stock and tested in ISO 17025 labs against NBR 10281 or NBR 16098.

- Certificate Issuance: If all audits and tests pass, the OCP issues the certificate.

- Maintenance: Valid 3–4 years, requiring annual factory audits and partial re-testing of samples.

Import Considerations

For importers (typically sourcing from China), the process has specific nuances.

- Legal Representative: Importer must be a Brazilian legal entity (CNPJ) and is legally responsible for the product.

- Batch Certification (Model 1b): One-off imports are inspected and tested at the port/warehouse; certificate applies only to that batch—fast for compliance but costly per unit.

- Foreign Factory Audit (Model 5): For ongoing trade, the OCP audits the overseas factory, enabling a 4-year certificate and smoother future shipments.

Manufacturing and Quality Control Implications

The strictness of the Brazilian testing regime dictates manufacturing decisions.

Supply Chain Management

- Brass Quality: High-quality brass ingots are required to pass leakage and toxicity tests; scrap or unknown alloys risk lead contamination and porosity.

- Component Validation: Key parts like ceramic cartridges and aerators (e.g., Sedal, Kerox, Neoperl) must meet standards, as the faucet’s certification depends on their quality. Proof may be requested by the OCP.

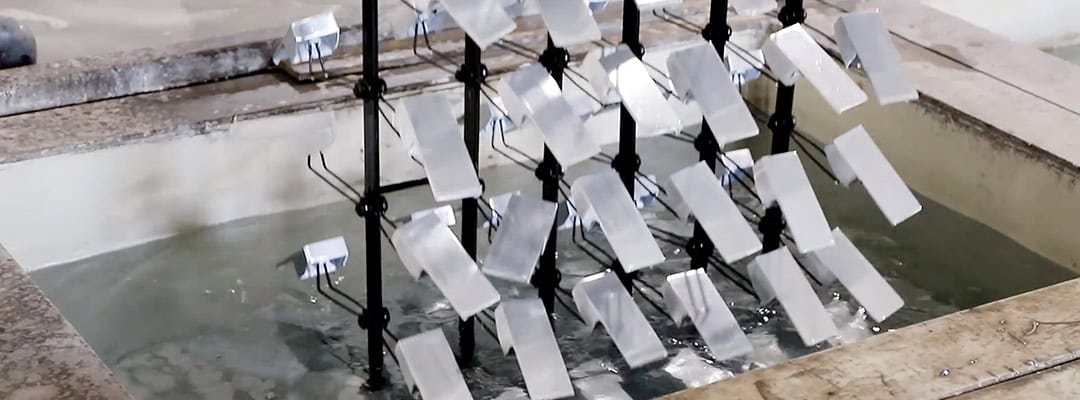

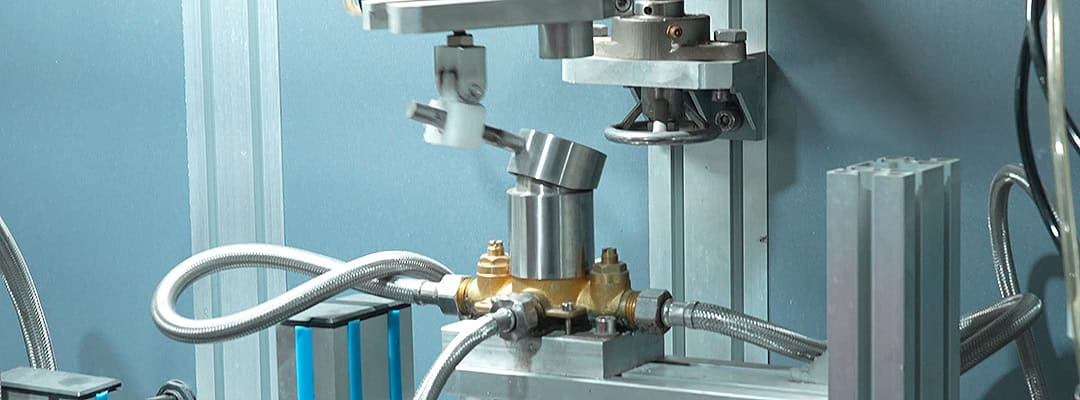

Production Line Testing

To ensure the “sealed” samples pass the audit, factories must implement rigorous End-of-Line (EOL) testing.

- 100% Pressure Test: Every faucet is tested (air or water) for leaks; air testing is faster and cleaner.

- Torque Control: Bonnet nuts are torque-controlled to secure the mechanism without over-compression, preventing excess friction and wear.

The Economics of Compliance

Certification is a significant cost center.

- Direct Costs: OCP fees, Laboratory testing fees (which can run into thousands of Reais per family), Auditor travel expenses.

- Indirect Costs: Maintaining the Quality Management System, scrapping non-compliant material, managing the administrative burden of Orquestra.

- ROI: The return comes from access to the “Formal Market” (Big Box retailers, Government tenders) and price premiums associated with the “Quality” perception of the INMETRO seal.

Future Outlook and Trends

Water Conservation and Efficiency

Future NBR revisions will likely emphasize water efficiency. The PBE labeling program already grades consumption, and mandatory flow limits may be integrated into certification.

Electronic and Smart Faucets

Sensor faucets add electrical safety requirements under Portaria Inmetro 371 (IEC 60335-1). If they also filter water, they must comply with three regulations: Electrical (371) + Hydraulic (NBR 10281) + Health (344).

Conclusion & Recommendation

Brazilian faucet certification is complex but essential. INMETRO, NBR standards, and relevant Portarias ensure safety, hygiene, and durability, protecting retailers, installers, and consumers.

Recommendation: Work with suppliers experienced in compliant brass, cartridges, and filtration components, with robust quality control and proper documentation. This reduces risk, speeds customs, and strengthens your brand’s credibility.

FAQs

About Luxuryhome

Luxuryhome is not just a faucet manufacturer or wholesaler, but more like a partner who can provide you with more added value.

We are united in our determination to produce China-made bath and kitchen fixtures adhering to the highest ethical principles. You have our promise!

More post you may interested in