When selecting faucets for high-end projects, it’s easy to focus on design and finish. But one invisible factor matters just as much: local water quality.

Minerals, disinfectants, and acidity can quietly damage faucets from the inside, causing leaks, corrosion, and costly callbacks. This guide explains how hard water, acidic water, and chloramine affect materials—so you can choose faucets that perform reliably for years, not just look good on day one.

The Hard Water Reality – A Case Study in Tribology

This scenario is all too familiar. A luxury residential project in a hard-water region installs high-end designer faucets. For the first few months, everything works perfectly—smooth handles and clean, aerated flow.

Then problems begin. Handles grow stiff, faucets start dripping, and some valves eventually seize completely. Water flow becomes uneven and splashes everywhere.

This wasn’t caused by cheap manufacturing. It was a material compatibility failure—hard-water» minerals reacting with the cartridge materials. To prevent this, you must understand how scale builds and how it affects internal components.

The Mechanism of Scale Formation

Hard water contains high levels of calcium and magnesium. While safe to drink, these minerals are tough on plumbing.

Inside a faucet cartridge, pressure drops and temperature changes cause these minerals to turn into calcium carbonate scale. This rock-like buildup forms directly on the ceramic valve’s sliding surfaces, leading to stiffness, leaks, and eventual failure.

The Ceramic Cartridge: A Battle of Hardness

The core of a modern luxury faucet is the ceramic disc cartridge, which uses two sliding discs to control water flow and temperature.

- The Microscopic Gap: Ceramic discs seal by being perfectly flat, preventing water from passing between them.

- The Intrusion: In hard water, tiny limescale crystals form at the disc surfaces.

- The Abrasion: When the handle moves, these crystals enter the sealing zone and act like a grinding paste.

- The Failure: Over time, scale bridges the gap and cements the discs together—causing valve seizure.

The Luxuryhome Solution: Proactive Maintenance & Education

Many manufacturers rely only on material upgrades, but Luxuryhome» knows even the hardest materials can fail under extreme mineral buildup. Our solution is a Client Education and Maintenance Support Protocol.

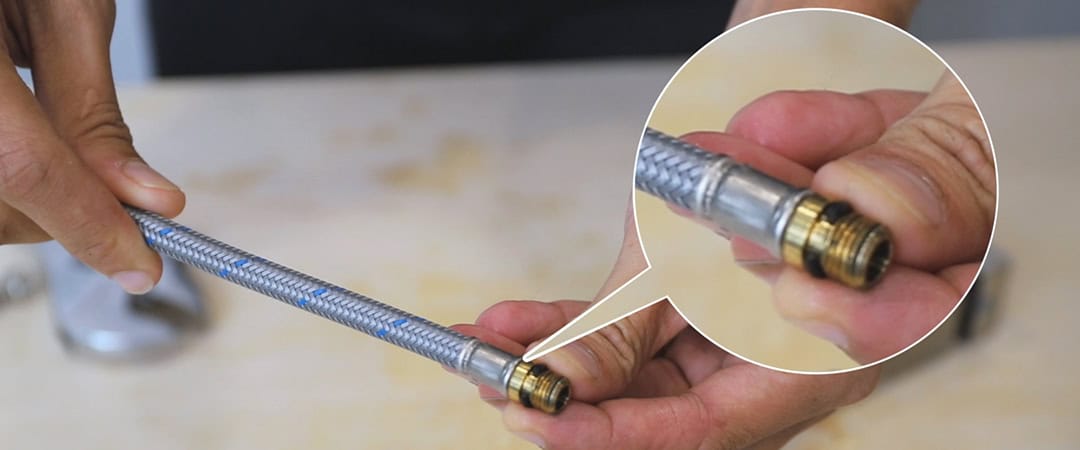

We view fixture longevity as a partnership. To prevent valve seizure and aerator clogging, we provide wholesalers and engineers with professional cleaning videos and maintenance guides for end-users.

- Dissolving the Bond: Our guides show homeowners or maintenance teams how to use a vinegar soak or descaling agents to dissolve calcium carbonate before it hardens.

- Restoring Flow: Videos demonstrate removing and soaking the aerator to eliminate mineral buildup, restoring a smooth, splash-free stream—no plumber needed.

By educating users, we turn potential product failures into simple maintenance routines, greatly reducing warranty claims and callbacks.

Systemic Prevention: The Water Softener Recommendation

For areas with water hardness above 7–10 gpg, Luxuryhome advises installing water softeners.

- Root Cause Mitigation: Softening replaces calcium and magnesium with sodium or potassium, neutralizing scale formation.

- Protection & Longevity: This prevents scale in ceramic discs and extends the life of faucets, piping, and water heaters.

The Acid Test – Dezincification and the Integrity of Brass

Hard water adds scale, but acidic or aggressive water removes material—this leads to dezincification».

Brass, an alloy of copper and zinc, is valued for strength and corrosion resistance, but not all brass alloys withstand aggressive water equally.

The Chemistry of the “Pink” Corrosion

Standard plumbing brass (CW617N) has ~60% copper and 40% zinc. Zinc adds strength but is less noble than copper.

In acidic or chloride-rich water, a galvanic reaction forms, and zinc is selectively leached into the water, weakening the alloy.

- The Residue: A porous, sponge-like copper matrix remains.

- Visual Indicator: Brass turns from golden-yellow to reddish-pink.

- Structural Failure: The brittle copper has no strength—threads crumble and valve bodies can snap under pressure or wrench torque.

The Phenomenon of “Meringue” Buildup

Dezincification not only weakens brass but can block it. Dissolved zinc reacts with carbonates to form white “meringue,” restricting flow. Unlike limescale, this comes from the pipe itself breaking down.

In aggressive water, uneven flow could be from zinc oxide buildup, and seizure from fused valve threads.

Material Selection: The DZR Imperative

For engineering contractors working in regions with aggressive water, the specification of Dezincification Resistant (DZR) Brass is not optional—it is critical.

- The Alloy Difference (CW617N vs. CW602N)

-

- CW617N (Standard Brass): Mix of alpha and zinc-rich beta phases; beta leaches easily. In aggressive water, fittings can fail in 2–5 years.

- CW602N (DZR Brass): Heat-treated with additives like arsenic to stabilize zinc in alpha-phase, preventing dezincification.

- Strategic Sourcing for Wholesalers

For coastal or well-water projects, look beyond finish and check material composition.

-

- Risk: Standard CW617N brass can leak within 5 years.

- Solution: Use DZR brass (CW602N) or lead-free silicon brass (C69300) for durability, dezincification resistance, and compliance.

The Chemical Assault – Chloramines and Rubber Embrittlement

The third hidden challenge targets the seals—O-rings and gaskets. The threat isn’t minerals, but chemicals added to keep water safe.

Municipal water was once treated with chlorine, which can form harmful byproducts. Many cities now use chloramine, safer for humans but much harsher on rubber seals.

The Mechanism of Elastomer Failure

Rubber seals in faucets are typically made of NBR (Nitrile Rubber) or EPDM (Ethylene Propylene Diene Monomer).

- NBR Failure: Chloramine degrades nitrile rubber, causing leaks and black particles.

- EPDM Failure: Standard EPDM can swell, increasing handle friction.

- Symptom: A swollen O-ring increases handle friction. In the case study, while scale caused the seizure, the swollen O-ring made the handle heavier and harder to turn.

The Solution: Chloramine-Resistant Compounding

Specialized EPDM resists chloramine damage. The key is the curing process, which cross-links the rubber during manufacturing.

- Sulfur-Cured (Standard): Vulnerable to chemical attack.

- Peroxide-Cured (Premium): Peroxide curing creates stronger carbon-carbon bonds between the polymer chains. These bonds are highly resistant to the oxidative attack of chloramines.

Certified Durability: Luxury faucets now use chloramine-resistant EPDM for all wetted seals, tested to NSF/ANSI 61 and WRAS standards. Generic seals in chloraminated water risk leaks and callbacks. OEM-specified seals ensure long-term reliability.

The Aesthetics of Durability – PVD vs. Chrome

While internal parts combat water chemistry, the external finish faces salt, humidity, and cleaners. In coastal luxury homes, the finish often fails first, causing client complaints.

The Limits of Electroplating

Traditional chrome plating deposits nickel and chromium on brass. Shiny but porous, it allows salt ions in coastal environments to reach the brass, causing corrosion and damage.

- Pitting: Small black spots appearing on the chrome.

- Peeling: The plating flaking off as the brass corrodes underneath.

- Tarnishing: The loss of luster due to oxidation.

The PVD Revolution

Physical Vapor Deposition (PVD) applies a finish in a vacuum chamber. Metal ions bond with nitrogen to form a durable, ceramic-like coating, unlike traditional chemical baths.

- Performance Gap: Finish durability is tested with Neutral Salt Spray (NSS), exposing the fixture to a saline mist until corrosion appears.

-

- Standard Chrome: Typically passes 24 to 96 hours before showing signs of corrosion.

- PVD Finish: Can withstand 1,000 to 2,000+ hours of salt spray exposure without degradation.

- Hardness and Scratch Resistance PVD coatings are also incredibly hard.

-

- Chrome Hardness: ~900 HV (Vickers).

- PVD Hardness: ~2,500 HV. A PVD finish resists micro-scratches, keeping its showroom shine for life. For luxury projects, PVD is the best protection against corrosion.

The Economic Argument for Over-Engineering

For wholesalers and contractors, all these technical details—alumina purity, DZR brass, peroxide curing, and PVD—ultimately come down to one thing: cost.

It’s a common mistake to see these “over-engineered” materials as too expensive. In reality, when total cost of ownership and costly callbacks are considered, they are the more economical choice.

The Cost of the Callback

Consider the economics of a single warranty claim on a luxury project.

- The Problem: A dripping faucet in a high-end condo, caused by a seized cartridge or a degraded O-ring.

- The Labor: A licensed plumber must be dispatched. The call-out fee alone is often $150 to $300.

- The Administration: The contractor’s project manager must field the complaint, source the part, and coordinate the schedule.

- The Reputation: To the luxury homeowner, a dripping tap in a million-dollar home signals “cheap quality.” The damage to the builder’s brand is incalculable.

If a project with 100 units uses standard materials in a hard water area, and sees a 10% failure rate in Year 2, the cost of remediation will far exceed the initial savings of choosing a cheaper fixture.

The “Insurance” of Premium Materials

Upgrading to a fixture that utilizes a 99% alumina cartridge, DZR brass, and PVD finish might increase the unit cost by 15-20%. However, this premium acts as an insurance policy.

- Longevity: Instead of failing in 2-3 years, the fixture is engineered to last 10+ years in aggressive conditions.

- Maintenance: “Rub-clean” aerators reduce the need for maintenance staff interventions.

- Stability: DZR brass ensures that the pipes behind the wall do not become a flooding liability.

For the wholesaler, presenting this “value engineering” argument—framing the higher initial cost as a risk mitigation strategy—is a powerful sales tool. It demonstrates technical expertise and a commitment to the client’s long-term satisfaction.

Conclusion: Mastering the Invisible

The seized-faucet case is a clear warning: water is not passive. It is a chemical force that degrades ceramics, corrodes metals, and shortens the life of rubber components.

For luxury-home projects, true “luxury” must go beyond appearance—it must include long-term mechanical reliability. By understanding scale, acidity, and chloramines, and specifying DZR brass, chloramine-resistant elastomers, and PVD finishes, professionals can prevent premature failures.

Equally important is choosing a reliable, technically proven supplier—such as Luxuryhome—as part of the risk-control strategy. In a reputation-driven industry, durability and supplier credibility together form the real competitive advantage.

FAQs

About Luxuryhome

Luxuryhome is not just a faucet manufacturer or wholesaler, but more like a partner who can provide you with more added value.

We are united in our determination to produce China-made bath and kitchen fixtures adhering to the highest ethical principles. You have our promise!

More post you may interested in