Planning to stock sanitary fittings for a Danish project—or filling a container for Scandinavia? Welcome to one of Europe’s toughest regulatory markets.

Unlike much of the EU’s simple “CE and go” approach, Denmark is different. Because the country drinks natural, unfiltered groundwater, it strictly controls anything that touches tap water. Buyers must clear two major hurdles: GDV (health) and VA (noise/mechanical).

Choose the wrong products and you risk inspector rejection—or costly replacements after installation. Here’s your quick guide to choosing the right supplier.

The Danish Regulatory Architecture

Denmark’s faucet and shower requirements come from its unique water philosophy. Because the country drinks naturally filtered groundwater—with almost no chemical disinfection—there is zero tolerance for heavy metals, organic migration, or anything that could promote bacterial growth. This purity mindset drives some of Europe’s strictest rules on materials in contact with tap water.

The Two Compliance Pillars

Denmark’s old unified approval system was split after the EU CPR reforms. Today, every product must navigate two separate pillars:

- Health (Mandatory – GDV):

Managed by the Ministry of Social Affairs and Housing. Focuses on metal migration (lead, nickel, cadmium), organic carbon from plastics/rubbers, and taste/odor. GDV is the official proof.

- Mechanical (Voluntary – VA):

Based on Danish Building Regulations. Covers flow rates, pressure, endurance, backflow prevention, and noise. Verified through the VA approval by ETA-Danmark.

Key Authorities

- Social- og Boligstyrelsen»: Top authority for GDV approvals; processes applications and maintains the approved product database.

- ETA-Danmark»: Issues voluntary VA approvals showing compliance with mechanical and acoustic requirements (BR18).

- Sikkerhedsstyrelsen: Oversees market surveillance and marketing compliance.

- DTI and other labs: Accredited labs performing chemical and physical testing for both GDV and VA.

The “Drinking Water” Definition

Under Danish law, “drinking water” means cold water intended for consumption. This creates a key difference:

- Faucets: Always considered drinking-water devices → GDV required.

- Showers: Normally for hygiene, not consumption → usually exempt from GDV, unless marketed or installed as a drinking-water outlet (e.g., kitchen pull-out sprays).

The GDV Scheme: Mandatory Health Certification

The Godkendt til Drikkevand (Approved for Drinking Water) scheme, symbolized by the “Drop” logo (Dråbe-mærket), is the mandatory license to sell and market plumbing components in Denmark. It is illegal to market a faucet for drinking water purposes in Denmark without this approval or an explicit legal equivalent.

Legislative Basis: Executive Order 1007

The GDV scheme is based on Executive Order no. 1007 (2016)», updated by Order no. 656 (2023). It replaced the older Order 666 and simplified approvals by accepting certain foreign certificates.

Under this law, factory-made components that contact drinking water may be marketed in Denmark only if they have GDV approval or a recognized certificate from Germany, the Netherlands, or Sweden. Compliance proof rests fully with the manufacturer or importer.

Product Categories Requiring GDV

Based on these criteria, the following items are strictly regulated and require the GDV mark:

- Faucets: Kitchen mixers, bathroom basin mixers, pillar taps.

- Pipes: Copper, stainless steel, PEX (cross-linked polyethylene), PE-RT, and multilayer pipes used for supply lines.

- Fittings: Brass fittings, press fittings, manifolds, and T-pieces.

- Valves: Ball valves, stop valves, and non-return valves installed in the supply line.

- Water Treatment: Filters, softeners, and coolers installed in the fixed line.

Testing Requirements and Methodology

Products requiring GDV certification must undergo strict testing at a DANAK-accredited lab or any EA/ILAC-recognized equivalent.

- Inorganic Migration (Metals)

Metal parts are tested for heavy-metal release, especially:

-

- Lead (Pb): Denmark enforces an extremely low limit—effectively 5 µg/L at the tap, and rarely accepts total migration above 20 µg. Far stricter than the EU’s 10 µg/L.

- Nickel (Ni): Limit of 20 µg/L, relevant for chrome-plated parts.

- Cadmium (Cd): Limit of 2 µg/L.

Test methods: Typically EN 16056/16058 with long-term stagnation tests (up to 26 weeks). Stable 10-day results may be accepted. The older Nordic “NKB method” is also referenced.

- Organic Migration (Plastics & Elastomers)

Plastics, hoses, cartridges, and O-rings are checked for:

-

- TOC: To assess organic leaching that can fuel bacterial growth.

- Taste & odor: Panel testing ensures no sensory changes.

- Specific migration: Additives must meet SML limits.

- Toxicology review: Required if rubber or polymer ingredients fall outside the EU 10/2011 positive list—often a costly step.

Mutual Recognition: The “Fast Track”

To reduce unnecessary re-testing, Denmark accepts certain foreign health certificates as valid documentation for GDV applications—making this the fastest route for manufacturers.

Denmark recognizes:

- Germany: KTW-BWGL and DVGW (W270) certificates. Older KTW certificates are no longer accepted.

- Netherlands: Kiwa Water Mark or ATA.

- Sweden: Type Approvals from Kiwa Sweden or RISE.

- 4MS documentation: Compliance with the 4MS Common Composition List is strongly favored.

Important: Even with a foreign certificate, manufacturers must still submit it to the GDV Secretariat, pay the fee, and obtain an official Danish GDV approval number before using the GDV mark.

The VA Scheme: Mechanical and Acoustic Excellence

The GDV scheme protects drinking-water safety, while the VA scheme—run by ETA-Danmark—verifies durability, performance, and, importantly for Denmark, low noise. Though voluntary, VA is widely seen as the market’s quality benchmark.

The “Voluntary” Label vs. Market Reality

Although VA approval is legally voluntary, it has become the practical standard. Many public and commercial projects specify VA-approved products, making the mark almost essential.

- Installer protection: VA approval shifts liability away from installers—without it, they must prove a product was fit for purpose in the event of leaks or noise issues.

- Insurance: Insurers also favor VA-approved products when evaluating water-damage claims.

Acoustic Requirements: The ISO 3822 Standard

The most challenging aspect of VA certification for foreign manufacturers is the acoustic noise limit. Danish construction standards are hypersensitive to noise transmission in multi-story buildings.

- Standard: Testing is conducted according to ISO 3822 (Acoustics – Laboratory tests on noise emission from appliances and equipment used in water supply installations).

- The Test: The faucet is mounted in a “reverberation room.” Water is flowed through it at a standardized pressure (typically 3 bar / 0.3 MPa). The sound pressure level (Lap) is measured.

| Noise Class | Noise Limit (Lap) | Application in Building Regulation (BR18) |

|---|---|---|

| Group 1 | ≤ 20 dB(A) | Universal Application. Can be used in all housing types, including apartments with shared walls. This is the “Gold Standard” for Danish taps. |

| Group 2 | 20 dB < Lap≤ 30 dB(A) | Restricted Application. Permitted in detached houses or utility rooms. In apartments, allowed only if building insulation is superior or water pressure is limited (<300 kPa). |

| Unclassified 3 | > 30 dB(A) | Limited Market. Generally deemed unsuitable for residential sanitary installations near sleeping/living quarters. |

Mechanical and Hydraulic Requirements

Beyond noise, the VA approval verifies compliance with EN 817 (Single-lever mixers) or EN 200 (Two-handle taps).

- Flow Rates: Verification of eco-claims (e.g., “Water Saving”). Standard basin taps are often restricted to 5-6 L/min.

- Pressure Resistance: The component must withstand 1.5 times the nominal pressure (PN) without leaking or deformation. For a PN10 tap, this means testing at 16 bar.

- Backflow Prevention (EN 1717) is essential for shower handsets. A shower hose must include a check valve to stop contaminated water from siphoning back into the drinking supply if the handset falls into a tub or toilet.

VA Approval Categories and Validity

VA approvals are categorized by complexity, which dictates the fee structure.

- Class 1: Simple components (e.g., pipe fittings, aerators).

- Class 2: Standard components (e.g., taps, mixers, valves).

- Class 3: Complex systems (e.g., large units, drainage systems).

- Validity: Certificates are typically issued for 5 years, renewable upon application and payment of a renewal fee.

Technical Deep Dive: Materials and Toxicology

Danish requirements for both GDV and VA align closely with the 4MS initiative, which sets common hygienic standards for materials.

Metallic Materials: Shift Toward Lead-Free

Denmark strongly favors materials listed in the 4MS Common Composition List.

- Standard brass (CW617N) performs poorly in Danish groundwater due to dezincification.

- DZR brass (CW602N, CW625N, CW511L) is generally required.

- Low-lead or lead-free alloys like CW511L and silicon brass (CW724R) help meet Denmark’s <5 µg lead limit.

- Stainless steel (304/316) is widely accepted and consistently passes migration tests.

Polymers and Elastomers

Soft parts are the most common cause of GDV test failures.

- PEX is preferred for flexible hose liners.

- EPDM must be peroxide-cured to avoid taste/odor and nitrosamine issues.

- Toxicology: Non-certified rubber or plastic compounds often fail TOC or cytotoxicity tests; full raw-material traceability is usually required.

Administrative Procedures and Fees

Navigating the bureaucracy of two separate agencies requires precision. This section details the costs and steps for the 2025/2026 period.

Submission: Applications are submitted digitally via Virk.dk or email. Documentation Checklist:

- Application Form: Electronic form.

- Product List: Detailed list of all SKUs (Stock Keeping Units) in the family.

- Drawings & Photos: Exploded views identifying all wetted parts.

- Bill of Materials (BOM): Listing material type (e.g., CW511L), trade name, and wetted surface area (mm²).

- Evidence: Either a full Test Report (Route A) or a Foreign Certificate (Route B).

- Inspection Agreement: Signed contract with an inspection body (e.g., DTI, Kiwa) for annual surveillance.20

Fee Structure (GDV): The GDV scheme is fee-funded based on time spent (“Time and Material”). There is no flat fee.

- 2025 Hourly Rate: 1,075 DKK per hour.

- 2026 Hourly Rate (Proposed): 910 DKK per hour.

- Estimate: A straightforward application based on a German certificate might take 5-8 hours (~5,000 – 8,000 DKK). A complex application requiring toxicological review could take 20+ hours.

Applying for VA (ETA-Danmark)

Submission: Direct submission to ETA-Danmark». Fee Structure (Fixed): VA fees are fixed based on product class. The following table approximates the cost structure.

| Product Class | Initial Approval (5 Years) | Renewal (5 Years) |

|---|---|---|

| Class 1 (Simple) | ~ 4,750 DKK | ~ 2,900 DKK |

| Class 2 (Taps/Valves) | ~ 7,650 DKK | ~ 4,550 DKK |

| Class 3 (Complex) | ~ 12,400 DKK | ~ 7,450 DKK |

Note: If a product is modified during the period, an update fee (max 3,000 DKK) applies.

The Self-Check (Egenkontrol)

Both schemes require a “Self-Check” program.

- Requirement: The manufacturer must have a Quality Management System (like ISO 9001) ensuring that the materials used in production match the approved samples.

- Audit: An external auditor must verify this annually. For companies with existing ISO 9001 certification and foreign approvals (e.g., DVGW), this is often a “paper audit” or combined with other inspection visits to minimize costs.

How to Vet a Supplier» (The Checklist)

You’re at a trade show or browsing a catalog, and the supplier says, “Yes, yes, we have Denmark approval.” Do not just take their word for it. Here is how you verify them on the spot.

Step 1: Ask for the Approval Number

A legitimate supplier will happily give you their GDV number (usually formatted like 04/00XXX) or their VA number (e.g., VA 1.42/XXXXX). If they hesitate, that’s a red flag.

Step 2: Check the “Godkendt til Drikkevand” Database

For health approvals, go to the official Danish database.

- Action: Ask for the certificate or look it up on trafikstyrelsen.dk or the dedicated GDV list.

- What to look for: Does the certificate cover the exact model you are buying? Often, a supplier has approval for one “master” model but tries to slip in cheaper variations that aren’t on the list.

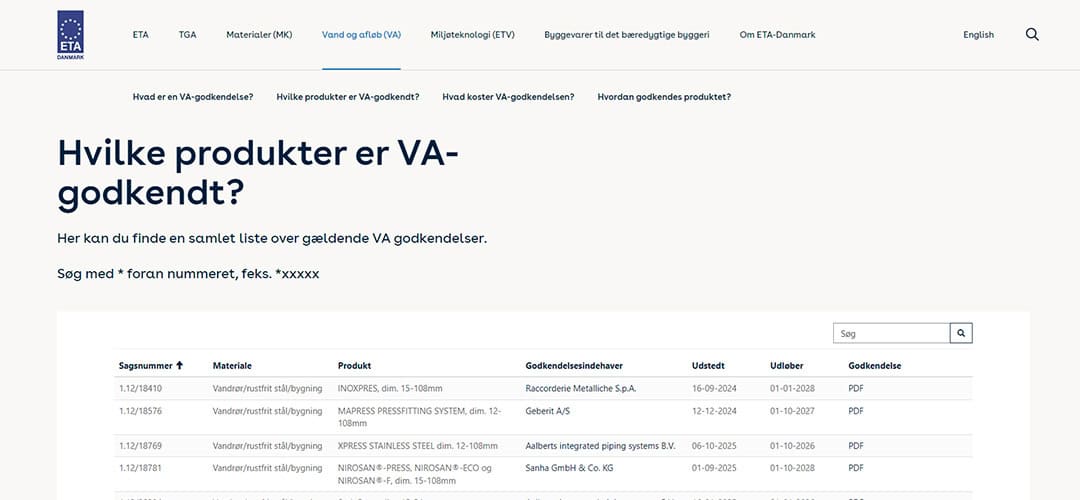

Step 3: Check the VA (ETA-Danmark) List

For mechanical/noise approvals, check ETA-Danmark.

- Action: Verify the noise class.

- The Trap: A supplier might have VA approval, but if it’s “Noise Group 2” and you’re trying to sell to a luxury apartment project, you’re going to get rejected. Always check if it is Group 1 or Group 2.

Step 4: Inspect the Materials

Ask for the BOM (Bill of Materials).

- Look at the brass type. If it says CW617N, be careful—that’s standard brass. In Denmark, you really want to see CW511L (Low Lead) or CW724R (Silicon Brass). If they can’t tell you the alloy, they don’t know the Danish market.

Step 5: The “System” Check for Showers

For shower hoses, ask about EN 1717 (Backflow Prevention).

- Even though showers don’t need GDV, the VA rules require that the handset cannot suck dirty bathwater back into the clean water pipes. The supplier must show that their handset or hose has a check valve that meets these standards.

Conclusion: Building Your Danish Reputation

Entering the Danish market is hard—but that barrier works in your favor. Once you secure GDV approval and meet VA noise specs, you instantly rise above non-compliant competitors.

Remember: GDV is your license to sell. VA is your license to win.

When you understand why “Group 1” matters, or why a shower hose doesn’t need a lead test, you become a trusted partner—not just a supplier. You help clients avoid delays, liability, and expensive rework.

Check the certificates, mind the lead levels, and get your “Drops” and dB ratings right. You’ve got this.

FAQs

About Luxuryhome

Luxuryhome is not just a faucet manufacturer or wholesaler, but more like a partner who can provide you with more added value.

We are united in our determination to produce China-made bath and kitchen fixtures adhering to the highest ethical principles. You have our promise!

More post you may interested in